Agenda - 2023

Day 1 (monday)

October

09

2023

EVENING RECEPTION

5:00 – 7:00 P.M.

This is the first opportunity to network with new industry partner providers and new and existing contacts with industry professionals.

Our deepest thanks to the AISC Certification Program for generously sponsoring this important opportunity.

Day 2 (Tuesday)

October

10

2023

7:30 AM – 8:00 AM

REGISTRATION

Please pick up your name tag and complete onsite registration before the conference starts.

Note:

Please be aware that breakfast is not included in your room registration at the DoubleTree Hilton Omaha Downtown. You can enjoy a delicious breakfast at The Signatures Restaurant in the hotel lobby for $18 per person. They serve breakfast daily until 10 am, offering a variety of options for lighter eaters. Payment for breakfast will be your responsibility.

8:00AM – 8:15AM (OPENING REMARKS)

WELCOME FROM IOWA DOT KYLE FRAME

A special welcome to Iowa from Kyle, Structures Group Manager for Iowa DOT

8:15AM – 8:30AM (OPENING REMARKS)

WELCOME FROM our conference gold sponsor Valmont

A special welcome from Guy Nelson. Product Development Engineer, Valmont Structures.

8:15AM – 5:00PM (Design Group)

Design Group Meetings – DOT Engineers only

The Design Group consists of bridge engineers from each state DOT. Planned and led by your group leader Mike Nop the Iowa Design Representative and Bridge Project Development Engineer for Iowa DOT. Please submit your discussion questions to Mike and be sure to provide your answers back to him when you receive the complied listing. Michael.Nop@iowadot.us

Download the preliminary Agenda below

Note: Design participants must register for the conference to attend.

8:30 AM -9:30 AM

I – 74 Arch Bridge Design Challenges

The Iowa-Illinois Memorial Bridge was once the crown jewel of the I-74 Corridor, the gateway to the Quad Cities region. These twin suspension bridges spanned the Mississippi River and were once a vital link to the seven-mile expanse comprised of bridges, interstates, and communities. However, the economic successes in the Quad Cities region led to ever-increasing traffic demands and the outgrowing of the corridor’s existing infrastructure. The Iowa and Illinois Departments of Transportation decided on an ambitious corridor improvement plan to alleviate congestion and sustain the regional economies. There were several objectives to this plan, most notably the design, engineering, and construction of a new I-74 Mississippi River Bridge to replace the existing Iowa-Illinois Memorial Bridge.

Modjeski and Masters, as part of the Alfred Benesch design team, was tasked with providing final design services for the new I-74 Mississippi River Bridge. Located on a new alignment to the east, this is no ordinary crossing. The new I-74 Mississippi River Bridge features dual basket-handle arch bridges, one of which also supports a cantilevered pedestrian/bike trail and a scenic overlook region at mid-span. This presentation will discuss the iterations of design, the major design decisions, and the analysis and design concepts used to develop this signature structure.

Andrew Adams, PE and Project Manager / National Bridge group will take us through the challenges faced in this project.

9:30-10:30

Changes for Fracture Critical Designation

ason Lloyd PhD, PE, Manager of Bridge & Infrastructure Solutions at Nucor will addres two AASHTO Guide Specifications that were released at the end of 2018 with 2022 interims. They offer the analytical framework needed to revisit the way we evaluate redundancy in steel bridges considering system-level and member level redundancy for new or existing bridges. For the last four decades, the steel bridge industry has become accustomed to determining redundancy through engineering judgement married to a single approach, namely load path redundancy (referring to the number of girder lines). Publication of the 2022 NBIS has opened up design to other modes of redundancy and with it, new inspection protocols. Combined with the new AASHTO Guide Specifications, industry experts are now enabled to design outside the box that we put ourselves in 40 years ago. This presentation will briefly explore how owners and designers can take advantage of risk-based inspection intervals that are intrinsically linked to the redundancy of their steel bridge designs while exploring recommendations for implementation of the new redundancy terms in the 2022 NBIS (National Bridge Inspection Standard. NBIS also published significant changes to bridge inspection programs and accepted methods of steel bridge redundancy last fall.

10:30-11:00

MORNING BREAK

Generously sponsored by Modjeski and Masters, AMPP, and Bureau Veritas.

11:00-12:00

Lincoln Nebraska South Beltway – Steel Bridges Benesch consulting – Hawkins Construction

Benesch served as the lead designer and Hawkins the construction contractor for the Nebraska Department of Transportation on this major freeway project along the south side of Lincoln, Nebraska. When complete, the project will move traffic around Lincoln’s congested urban area and improve traffic flow on the existing urban street system. The project includes eight miles of new freeway, two system interchanges, three service interchanges and four overpasses. Benesch was responsible for designing 10 of the 20 bridges on the project. Bridge types under design include prestressed concrete girder bridge and plate steel girder bridges. Many of the bridges are on horizontal curves and involve complex geometry. The top-level flyover bridge is a 10-span steel plate girder structure with an overall length of 2,142-feet. Benesch and Hawkins will provide insights regarding steel bridges on the project from design through construction.

1:00-1:30

Innovation in Iowa’s Bridge Program

Iowa’s Bridge Engineer Jim Nelson will introduce us to the State’s bridge program and highlight some innovations the State has applied to recent projects

1:30-2:00

I-74 Arch Bridge Construction Challenges

Curtis Carter of Iowa DOT will review the construction challenges his team face.

2:00-2:30

I-74 Arch Bridge Virtual Tour

Cedric Wilkinson will provide a unique tour of the inside of the structure. He will also have a current drone flight video for a tour of the outside of the structure.

2:30-3:15

Innovation in MDOTs QA Consultant Program

Matt Filcek, MDOT, Structural Fabrication Engineer PE has innovated through several programs since he took the reigns of the Structural Fabrication Unit. One to know about is his CMFIP:

CONSULTANT MANAGED FABRICATION INSPECTION PROGRAM

Inspection consultant firms must demonstrate their ability to develop and implement a quality plan to assure project compliance to state specific requirements. The consultant organization demonstrates a management capability to support their QAIs assigned to MDOT projects technically and assures that MDOT is appropriately informed. That consultant management structure demonstrates their performance with data on specific KPIs to MDOT on a regular basis.

3:15-3:45

Afternoon Break

Generously sponsored by Pennoni, KTA Tator and D.S. Brown

3:15-3:45

Heat Straightening

What are the myths and realities in this process and is the use of force required? There may be some black magic involved after all.

The discussion will include the highlights of a heat straightening plan review, current FHWA documentation, as well as practical application pitfalls and what qualifies a good specialty contractor.

Kent Nelson is a Quality Specialist at DOT Quality Services. He is an invaluable resource for DOT and Agency clients for design and drawing reviews, problem-solving, and supplier assessment in both steel and prestressed concrete bridge fabrication. He is a registered PE in multiple states. Kent is formerly a fabrication engineer for MoDOT for over 19 years.

4:15-5:00

Accelerating Construction with Galvanized Steel Press-Brake Tub Girders

Guy Nelson, Product Development Engineer, Valmont Structures will present an update on the effect of these structures on cost and installation time to the owners who have used them.

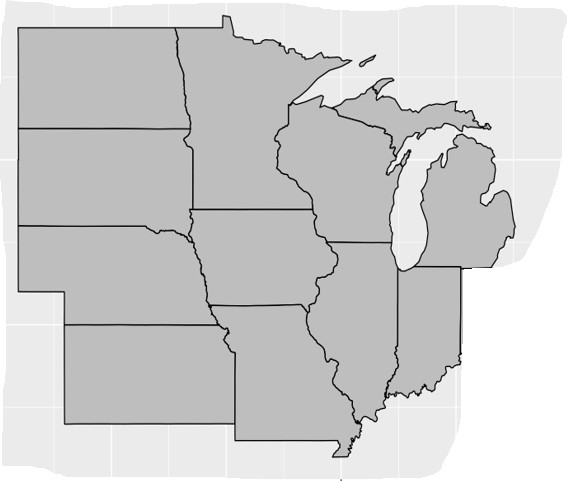

In pursuit of reporting zero critical bridges in Michigan, the Michigan Department of Transportation (MDOT) launched the Rebuilding Our Bridges pilot program in early 2021. The pilot program aims to eliminate the number of closed, serious, or critical bridges throughout the state. Nineteen bridges were identified for the program. Press-brake steel tub girders were selected for use on all bridge replacements due to their competitive price, quick installation times and long service life. MDOT hopes to develop Michigan’s larger Rebuilding Our Bridges program in a scalable and repeatable process using this pilot project. The program is reimagining bridge replacement. All individual bridges were completed on time and the entire project was complete 1 year ahead of schedule.

Additionally, the Tennessee DOT selected and designed their own Press-brake Tub steel tub girder superstructure for an emergency bridge replacement project in Sevier County, TN. Receiving the beams with only a six-week lead-time, TDOT was able to completely replace this bridge in less than 3 months. TDOT is now working on their own Press-brake tub girder standards.

And finally, AASHTO has recently awarded the press-brake tub girder technology the Innovation Initiative award and deemed this a “ready to implement” technology.

5:00 – End of Scheduled Day

Evening on your own

Reconnect with new contacts over dinner or cocktails or ask more about what you heard today, or relax and get to know attendees in a comfortable environment.

5:30

NCSC State Representatives Meeting

This is an invitation-only meeting. Representatives will meet to discuss opportunities to make NCSC grow and be a greater resource for the Bridge Engineers and Technicians of the member states year-round. Dinner meeting at the hotel.

Day 3 (Wednesday)

October

11

2023

7:45-8:00

Announcements and Schedule review

Kyle Frame will review the schedule of the day and present any announcements.

8:00-8:30

NSBA Program Update

NSBA’s Tony Peterson will present an update to NSBA’s services and some current projects.

8:30-9:00

2023 AASHTO LRFD Steel Bridge Fabrication Specifications: What are they, why are they, what comes next, and how do you fit in?

Heather Gilmer, Senior Engineer at Pennoni, was instrumental in the concept and execution of this document. She will cover the reasons this document was created; its effects on the AASHTO Bridge Construction Specifications, AASHTO/AWS D1.5, and AASHTO/NSBA Steel Bridge Collaboration S2.1; and what this means for DOTs.

9:00-9:30

AISC Certification Program Update

Todd Alwood will update us on AISC certification changes

9:30-10:00

Break

10:00-10:45

BIL and Bridge bundling

The session will present bridge bundling and innovative design as they pertain to the opportunities in the Bipartisan Infrastructure Law (BIL). An example bridge bunding case study that used Simple-for-Dead, Continuous-for-Live (SDCL) bridge design will be discussed, along with considerations for sustainability and resiliency in the Bipartisan Infrastructure Law. The session will close with available technical resources and educational opportunities that can help bridge owners and engineers in their efforts to manage their bridge infrastructure.

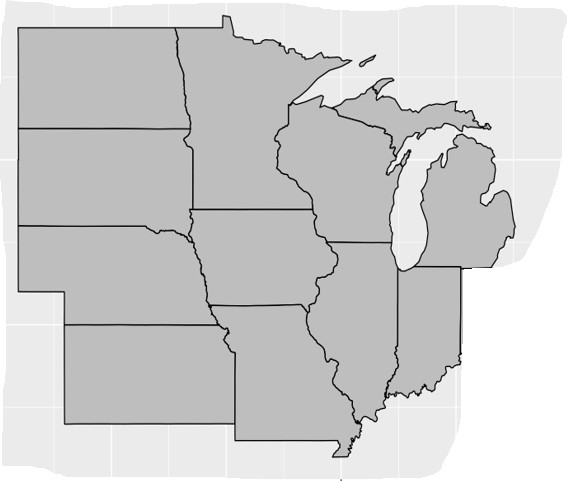

Dr. Michael Barker, PE, University of Wyoming, Director of Education, Short Span Steel Bridge Alliance received his BS and MS in Civil Engineering from Purdue University and his PhD from the University of Minnesota. He is a Professor of Civil & Architectural Engineering at the University of Wyoming.

10:45-11:30

AMPP Program Update

The Association for Materials Protection and Performance will present:

- A short update on the merger of NACE and SSPC and the impact the merger has had on Contractor Accreditations, Surface Prep and Coating Standards commonly used on steel and Coating Inspector Certification

- A short update on changes to commonly referenced coating standards (e.g., Blast cleaning and Application standards)

- An Update on Joint SSPC/AISC Shop Certification Standard Update

_____

Michael Damiano will also address the current use of metalizing in the bridge world from AMPP perspective. He will have some thoughts on best practices in specifying using states’ special provisions. and some of the best practices in QA inspection of the process.

11:30-12:00

States Future Lettings and closing